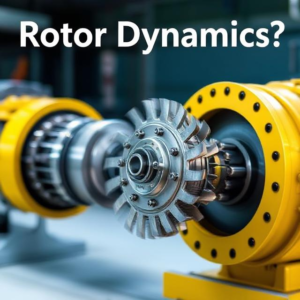

What is Rotor Dynamics?

Rotor Dynamics is the study of the behavior of rotating parts in machinery, such as motors, turbines, and helicopter blades, when they spin. It focuses on understanding the forces, motions, and vibrations that occur as a rotor (a rotating component) turns. Rotor dynamics is crucial for ensuring that these machines run smoothly, safely, and efficiently.

The goal of rotor dynamics is to:

- Understand how rotating parts move.

- Control vibrations, critical speeds, and other forces.

- Prevent issues like shaking, instability, or damage during rotation.

Engineers use rotor dynamics to design machines—ranging from helicopters to turbines—that operate without causing unwanted vibrations or structural damage.

Key Concepts in Rotor Dynamics

- Rotor:

A rotor is any rotating part in a machine. Examples include:- The spinning part of a fan.

- The blades of a helicopter.

- The rotating shaft inside an engine or turbine.

- Rotation:

Rotation refers to the turning of a rotor around an axis (similar to how a wheel or fan blade spins). The speed and stability of this rotation are crucial for the performance of the machine. - Vibrations:

As rotors spin, they can generate vibrations. While some vibrations are harmless, others can cause damage or result in unwanted noise. Managing these vibrations is essential for machine longevity. - Critical Speed:

Every rotor has a critical speed—a specific rotational speed at which it naturally vibrates or oscillates. If the rotor spins at this speed, the vibrations can escalate rapidly, causing damage to the rotor or the machine. Engineers aim to avoid the critical speed during normal operation.

Key Principles in Rotor Dynamics

- Center of Mass:

The center of mass is the point where the mass of the rotor is balanced. If the rotor is unbalanced, meaning more mass is on one side than the other, it can wobble or vibrate during rotation. Engineers design rotors with a balanced center of mass to avoid these issues. - Gyroscopic Effect:

When a rotor spins, it resists changes to its rotational axis, a phenomenon known as the gyroscopic effect. This effect helps stabilize rotating objects, such as bicycle wheels, and is critical in the design of vehicles like helicopters and airplanes, where it helps maintain stability during flight. - Damping:

Damping refers to the process of reducing vibrations during rotor rotation. Engineers incorporate dampers or other features to absorb vibrations, preventing damage to the rotor or the machine. - Torsional Vibrations:

Torsional vibrations involve the twisting of the rotor back and forth. If these vibrations are excessive, they can lead to rotor fatigue and eventual failure. To minimize torsional vibrations, engineers carefully design rotor systems to ensure stability and longevity.

Examples of Rotor Dynamics

- Helicopter Blades:

The blades of a helicopter rotate at very high speeds. Rotor dynamics is used to ensure that these blades do not shake or cause instability during operation. Additionally, the gyroscopic effect is studied to maintain stability during flight. - Turbines:

In power plants, turbines generate electricity by spinning. Rotor dynamics helps engineers ensure that the turbines rotate smoothly and do not vibrate excessively, which could lead to damage, power loss, or inefficiency. - Car Engines:

In internal combustion engines, the crankshaft is a rotating part. Rotor dynamics helps prevent harmful vibrations that could cause engine failure or degrade performance over time. - Wind Turbines:

Wind turbines use large rotors to capture energy from the wind. Rotor dynamics is important in designing these turbines to ensure they spin smoothly and vibrate minimally, which helps extend their lifespan and improves efficiency.

Rotor dynamics plays a critical role in ensuring that rotating machines operate efficiently, safely, and without causing damage or excessive wear. Whether designing helicopters, turbines, or automotive engines, rotor dynamics helps engineers create machines that perform optimally in a wide range of industries.