Power electronics systems are the backbone of modern electrical and energy systems. These systems, which include inverters, converters, motor drives, and power supplies, handle high voltages and currents and often operate under demanding conditions. As a result, they generate significant heat during operation.

Thermal management and protection mechanisms are critical for ensuring the safety, reliability, and longevity of power electronic components. This article explores the importance of thermal management, common cooling techniques, protection strategies, and emerging trends in power electronics thermal control.

Why Thermal Management Is Important

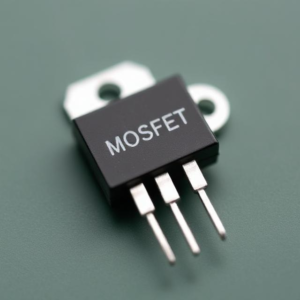

When power semiconductor devices like MOSFETs, IGBTs, and diodes switch or conduct high current, they experience power losses, primarily in the form of heat. If this heat is not properly managed, it can lead to:

-

Thermal runaway (where increasing temperature causes more losses and damage),

-

Component failure due to overheating,

-

Reduced efficiency and performance,

-

Shortened lifespan of the device.

Power electronic components typically have a maximum junction temperature they can tolerate (e.g., 150°C or higher). Keeping the device’s operating temperature below this limit is essential.

Sources of Heat in Power Electronics

-

Conduction Losses: Resistance in conductors and semiconductors causes I²R losses.

-

Switching Losses: Occur when a device turns on or off, especially at high frequencies.

-

Magnetic Losses: In inductors and transformers due to core hysteresis and eddy currents.

-

Leakage Currents: In devices like diodes under reverse bias conditions.

Thermal Management Techniques

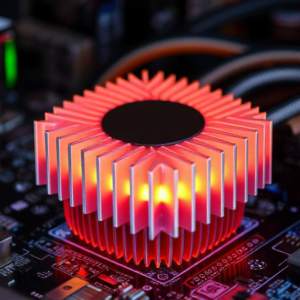

1. Heat Sinks

-

Made from materials like aluminum or copper.

-

Increase surface area to dissipate heat via convection.

-

Often paired with thermal interface materials (TIMs) for better heat transfer.

2. Forced Air Cooling

-

Uses fans to increase airflow over heat sinks or components.

-

Effective and low-cost but may introduce noise and require maintenance.

3. Liquid Cooling

-

Circulates coolant (e.g., water or glycol) through cold plates or channels.

-

Higher heat removal capacity than air cooling.

-

Used in high-power industrial or EV systems.

4. Thermal Interface Materials (TIMs)

-

Fill microscopic air gaps between device surfaces and heat sinks.

-

Improve thermal conductivity.

-

Examples: thermal paste, pads, phase-change materials.

5. Heat Pipes and Vapor Chambers

-

Transfer heat rapidly across a surface using phase change (liquid to vapor).

-

Common in high-density electronics and power modules.

6. Advanced Materials

-

Wide-bandgap semiconductors (SiC, GaN) can operate at higher temperatures.

-

Enable smaller heat sinks and simpler cooling systems.

Thermal Protection Methods

In addition to removing heat, protective systems must also detect and respond to thermal faults to prevent damage.

1. Temperature Sensors

-

Thermistors, RTDs, or built-in sensors monitor component temperatures.

-

Can trigger alarms or shutdown circuits when limits are exceeded.

2. Thermal Shutdown Circuits

-

Automatically turn off the system if temperatures exceed safe thresholds.

3. Current Limiting and Overload Protection

-

Prevent overheating due to excessive current draw.

-

Implemented through fuses, circuit breakers, or electronic current limiting.

4. Overvoltage and Undervoltage Protection

-

Protect against power supply fluctuations that can increase power losses and heat.

5. Short Circuit Protection

-

Rapid detection and shutdown of power in the event of a short to prevent thermal damage.

Design Considerations for Effective Thermal Management

-

Thermal modeling and simulation in the design phase.

-

Proper component placement for even heat distribution.

-

Use of thermal vias and copper pours in PCB design for better heat spreading.

-

Redundancy and fault tolerance to prevent cascading failures.

Emerging Trends and Innovations

-

Smart thermal management systems using AI or predictive algorithms for real-time control.

-

Integrated cooling solutions in semiconductor packaging (e.g., embedded microchannels).

-

Wireless temperature monitoring for better diagnostics and maintenance.

-

Use of nanomaterials and graphene for ultra-high thermal conductivity.

Conclusion

Thermal management and protection are essential aspects of power electronics design. Efficient heat removal not only improves performance and reliability but also ensures safety and compliance with regulatory standards. As devices become smaller and more powerful, advanced thermal techniques and smart protection systems will play a crucial role in shaping the future of power electronics.