Integrated Circuit (IC) Testing Techniques are methods used to check if an IC (a tiny electronic circuit, also known as a chip) works properly after it’s been manufactured. Think of it like testing a new smartphone to make sure all its features (screen, buttons, camera, etc.) work before selling it. Similarly, when a chip is made, it needs to be tested to ensure it functions correctly and doesn’t have any faults that could cause problems.

1. What is an Integrated Circuit (IC)?

An Integrated Circuit is a small chip that contains multiple electronic components like transistors, resistors, and capacitors, all built on a tiny piece of silicon. These chips are used in almost all modern electronics, from phones to cars to computers. An IC can perform various functions, like amplifying signals, processing data, or controlling devices.

2. Why Do ICs Need Testing?

ICs are very complex, with millions (or even billions) of components packed into a tiny space. Even a tiny error or defect in any part of the IC can cause the entire circuit to malfunction. So, after manufacturing, testing is done to make sure the IC works as expected before it’s sold or used in a product.

3. Types of IC Testing Techniques

IC testing techniques can be divided into different categories based on when and how the tests are performed. Here are the main types:

a. Visual Inspection

- What it is: A simple technique where the IC is visually inspected for obvious defects like missing pins, damaged solder joints, or incorrect markings.

- Why it’s used: It helps catch large-scale defects, like physical damage during manufacturing.

- Limitations: It can’t detect tiny faults or issues in the internal circuits, so it’s usually followed by other testing methods.

b. Functional Testing

- What it is: This test checks whether the IC works as expected by simulating the conditions it will face during normal use.

- How it works: The IC is powered up, and the outputs are measured to see if they match the expected results based on the inputs.

- Why it’s used: It checks if the IC performs its intended function, such as processing signals, turning on lights, or controlling devices.

- Example: For an IC in a phone, the test might check if it correctly processes touch input and displays the correct information on the screen.

c. Parametric Testing

- What it is: This test checks whether the IC’s electrical characteristics (like voltage, current, and resistance) fall within the correct range.

- How it works: The IC is tested under different conditions, such as varying temperatures or voltages, to make sure it behaves within specified limits.

- Why it’s used: It ensures that the IC will work reliably under different operating conditions.

- Example: A voltage regulator IC must ensure that it consistently provides the right voltage output even when the input voltage changes.

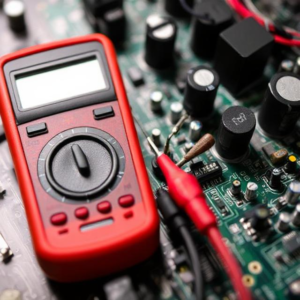

d. In-Circuit Testing (ICT)

- What it is: In-circuit testing checks the functionality of an IC while it’s still in the circuit board, without removing it.

- How it works: Specialized testing equipment is used to check the signals going in and out of the IC, ensuring it interacts correctly with other components.

- Why it’s used: It allows for testing the IC in its final form, as part of the complete system.

- Example: This test could check if the IC that controls the temperature in an air conditioner is working correctly in the circuit.

e. Boundary Scan Testing

- What it is: A test that uses a technique called JTAG (Joint Test Action Group), which allows for testing the IC by checking the connections between different pins on the chip.

- How it works: The chip is connected to a special testing device that sends signals through the IC’s pins to check if all internal connections are working.

- Why it’s used: It helps detect faults in the internal wiring or connections without requiring physical access to every pin or component inside the IC.

- Example: If an IC is part of a complex system, JTAG can test its connections to other parts of the system without needing to remove it.

f. Burn-In Testing

- What it is: This test stresses the IC by running it under extreme conditions (like high voltage or temperature) for a certain period to detect early-life failures.

- How it works: The IC is run for several hours or even days to ensure it will not fail unexpectedly during normal use.

- Why it’s used: It helps weed out defective ICs that might work initially but fail after a longer period of use.

- Example: Electronics that need to be very reliable, like medical devices or satellite systems, often undergo burn-in testing to catch any potential problems.

g. Scan Testing

- What it is: This technique uses special scan chains inside the IC to check each part of the circuit systematically.

- How it works: Test signals are applied to the scan chain, which checks different parts of the IC one by one to make sure they’re all working correctly.

- Why it’s used: It’s efficient because it can test many parts of the IC at once and find defects that might be hard to spot otherwise.

- Example: This type of test is often used in microprocessor chips to verify the functionality of each logic gate inside.

h. Automatic Test Equipment (ATE)

- What it is: ATE is a system that uses computers and specialized hardware to test ICs automatically, without much human intervention.

- How it works: The IC is placed into the ATE system, and it runs a series of tests on the chip to check its performance, signals, and functionality.

- Why it’s used: ATE systems can quickly test a large number of ICs and generate detailed reports, making them highly efficient for large-scale production.

- Example: Automated testing is often used in factories to test thousands of chips in a short amount of time.

4. Why is IC Testing Important?

- Ensures Quality: ICs are used in critical applications like medical devices, cars, and phones. Testing ensures they work reliably and safely.

- Prevents Failures: Catching defects early prevents expensive failures down the road.

- Improves Reliability: Thorough testing ensures that the IC will work as expected throughout its life, reducing the risk of malfunctions in end-user devices.

5. Challenges in IC Testing

- Complexity: As ICs get smaller and more complex, it becomes harder to test every part of the circuit.

- Cost: Advanced testing equipment can be expensive, especially for high-end ICs with millions of transistors.

- Speed: Testing must be done quickly in a manufacturing setting to avoid delays in production.

Summary

IC Testing Techniques are methods used to ensure that an integrated circuit (IC) works correctly after it’s manufactured. These tests include visual inspection, functional tests, parametric tests, in-circuit testing, and advanced techniques like boundary scan and burn-in testing. These methods help ensure that the IC functions properly, is reliable, and meets the required quality standards before being used in products. Testing is a critical part of the manufacturing process for all kinds of electronics, from simple devices like remote controls to complex systems in cars and medical equipment.