What is Soldering in Circuit Boards?

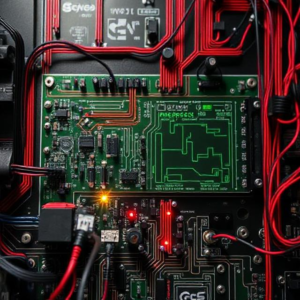

Soldering is the process of joining two or more electronic components to a circuit board using a metal called solder. Solder is a material that melts when heated and solidifies to create a permanent electrical connection.

In easy terms, soldering is like “gluing” the electronic parts (like resistors, capacitors, chips) to the board, but instead of glue, we use melted metal to create electrical connections.

Why is Soldering Important?

In electronics, components need to be connected to the circuit board to make a functional device. Soldering helps:

- Connect the components to the board.

- Conduct electricity between different parts of the circuit.

- Secure the components so they stay in place.

Tools Needed for Soldering:

Before we talk about the techniques, let’s quickly go over the tools you’ll need for soldering:

- Soldering Iron: A heated tool used to melt the solder.

- Solder: A metal alloy (usually made of tin and lead or tin and silver) used to make the connections.

- Soldering Iron Tip: The part of the iron that touches the board and components, usually pointed or chisel-shaped.

- Flux: A chemical that helps solder flow better and makes cleaner connections.

- Tweezers: To hold tiny components in place.

- Wire Cutters: To trim excess leads (the little legs of components that stick out after soldering).

- Soldering Iron Stand: A place to rest the hot soldering iron when not in use.

- Soldering Sponge: To clean the tip of the soldering iron.

Soldering Techniques:

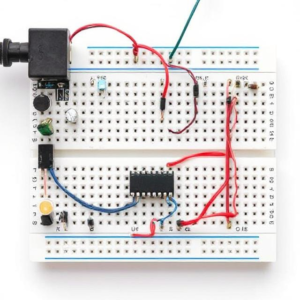

- Preparing the Circuit Board:

- Clean the board: Before starting, make sure the board is free from dirt, oils, or dust. You can wipe it with isopropyl alcohol or a soft cloth.

- Insert the components: Place the components (like resistors, capacitors, or chips) into their correct positions on the circuit board. If the components have leads (legs), push them through the holes in the board.

- Heating the Soldering Iron:

- Turn on the soldering iron and let it heat up. It usually takes around 1-3 minutes.

- The temperature should be around 350°C (662°F) for most soldering tasks.

- Once heated, clean the soldering iron tip by wiping it on a damp sponge to remove old solder and oxidation.

- Soldering a Component: Here’s the step-by-step technique for soldering:

- Heat the joint: Touch the soldering iron tip to the component lead and the circuit board pad (the metal ring around the hole) at the same time. Hold it for about 1-2 seconds. This heats both the component lead and the pad so the solder will flow properly.

- Apply the solder: While the joint is heated, apply a small amount of solder to the joint (not directly to the soldering iron tip). The solder should melt and flow around the lead and pad, creating a clean, shiny connection.

- Remove the soldering iron: Once the solder has flowed into the joint, remove the solder and then the soldering iron.

- Let it cool: Allow the solder joint to cool down for a few seconds. The solder should solidify quickly, leaving a firm, shiny connection.

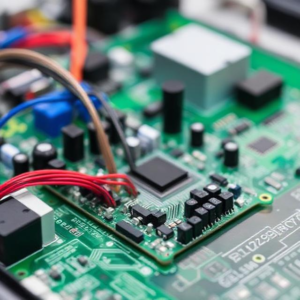

- Inspecting the Solder Joint: After soldering, check the joint carefully:

- Good solder joint: It should be shiny, smooth, and shaped like a small “volcano” around the lead and pad.

- Bad solder joint: It could be dull, cracked, or too much solder could be used. If this happens, you may need to heat it again and add or remove solder to fix it.

- Trimming Excess Leads: After soldering, there will often be excess metal leads sticking out of the component. Use wire cutters to trim these down, leaving just a small bit of the lead that is securely soldered to the board.

- Cleaning the Board: Once all the components are soldered, you can use a small brush and isopropyl alcohol to clean the board. This removes any leftover flux and makes the board look cleaner.

Common Soldering Mistakes and How to Avoid Them:

- Cold Joints: These occur when the solder doesn’t flow properly. It can happen if the iron isn’t hot enough or you don’t heat the joint long enough. To avoid this, always make sure both the pad and lead are heated properly before applying solder.

- Bridging: This happens when too much solder connects two adjacent pads or leads, causing a short circuit. Avoid this by using just the right amount of solder and being careful not to let it flow where it shouldn’t.

- Excessive Solder: Using too much solder can create large, sloppy joints. Only use as much solder as you need for a clean connection.

- Overheating Components: Some components are sensitive to heat and can be damaged if exposed to high temperatures for too long. Always try to keep the heat on the joint, not on the component itself, and work quickly.

Tips for Better Soldering:

- Practice: Soldering is a skill that improves with practice. Start with simple projects and work your way up.

- Work in a well-lit space: Good lighting helps you see the tiny parts and connections.

- Use a magnifying glass: For tiny components, using a magnifying glass or microscope can help you get precise with your soldering.

- Use the right solder: Make sure you’re using the right type of solder for your work. For most electronics, rosin-core solder is a good choice, as it has flux inside to help the solder flow better.

Conclusion:

Soldering is the key process for connecting components to a circuit board. By heating up the joint, applying solder, and letting it cool, you create a solid, reliable connection that allows the circuit to work. With practice, you can solder clean, professional-looking joints that will ensure your electronics function correctly.