Automation in electronics manufacturing is when machines and robots take over tasks that were once done by humans in the production of electronic devices, like phones, computers, or even TVs. The goal is to make the manufacturing process faster, more accurate, and cheaper.

Here’s how it works in simple terms:

1. Assembly Line Robots

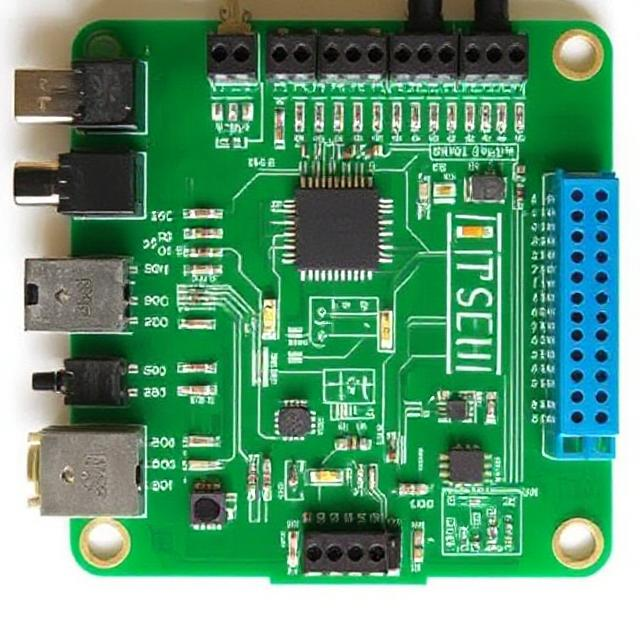

Instead of human workers putting parts together by hand, robots are used to assemble the electronic devices. These robots can pick up tiny parts, like chips, and place them on circuit boards. They can work quickly and precisely, reducing errors and making the whole process more efficient.

2. Machine Vision (Seeing Machines)

Machines can also “see” things using cameras and sensors. This is called machine vision. For example, they can check if the components are placed correctly on a circuit board. If something is wrong, the machine can fix it or alert workers, ensuring everything is made correctly without human intervention.

3. Automated Soldering

Soldering is the process of melting metal to create electrical connections between parts on a circuit board. In the past, this was done by hand, but now, automated machines can do it much faster and with greater precision. These machines can even solder tiny parts that would be hard for a person to handle.

4. Conveyor Belts

Parts and completed devices can move automatically along conveyor belts from one machine to the next. This makes the production line flow smoothly without any delays. Workers can monitor and manage the process without having to handle every part manually.

5. Testing and Quality Control

Automated testing systems check if the electronic devices are working properly. For example, they can run software on the device to make sure it’s functioning as expected, test for defects, or check for correct soldering. If something isn’t right, the system can either fix the problem or reject the defective item.

6. Data Collection and Analysis

Automation systems collect data about the manufacturing process, like how many items were made, if there were any problems, and how long it took. This data can then be analyzed to improve efficiency and quality, helping the company make better products faster.

Why is Automation Used?

- Speed: Machines can work 24/7 without breaks, so they can produce more items in less time.

- Accuracy: Automation reduces human error, making products more consistent and reliable.

- Cost-Effective: While robots and machines may have a high upfront cost, over time they help save money by reducing labor costs and increasing efficiency.

- Safety: Dangerous tasks, like handling hot equipment or sharp components, can be done by machines instead of people.

Examples of Automation in Electronics Manufacturing:

- Smartphones: Automated systems assemble the components, test the phone, and even package it.

- Computer Chips: Robots place tiny components on circuit boards, and automated machines test the chips to make sure they work.

- Television Screens: The process of assembling screens and testing them for defects is largely automated.

In summary, automation in electronics manufacturing is when machines, robots, and smart systems take over tasks like assembling, testing, and packaging electronic products, making everything faster, more accurate, and cost-efficient.