In electronics manufacturing, assembling components onto printed circuit boards (PCBs) is a crucial step. There are two main ways to assemble electronic circuits: automated assembly and manual assembly. Each method has its own advantages, disadvantages, and ideal use cases. Understanding the differences helps manufacturers choose the best process for their production needs.

What is Manual Assembly?

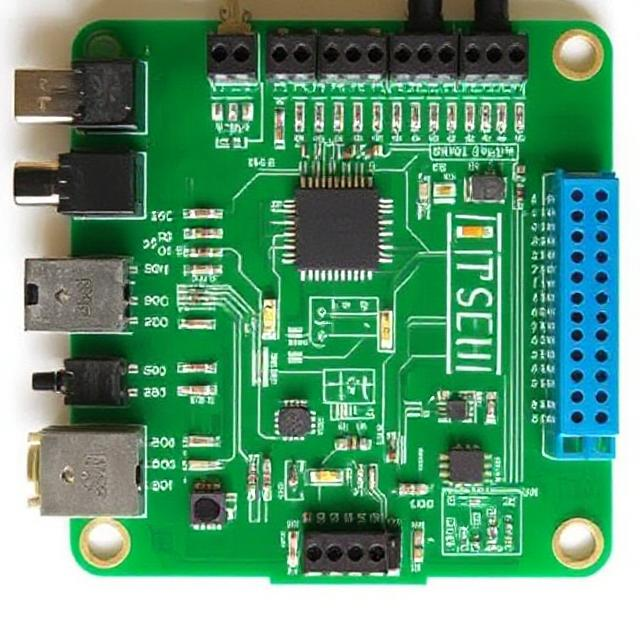

Manual assembly means that human workers physically place and solder components onto the PCB by hand. This method uses tools such as soldering irons, tweezers, and magnifying glasses to handle and connect components.

Characteristics of Manual Assembly:

-

Involves skilled labor placing parts onto the PCB.

-

Soldering can be done by hand or with simple equipment like soldering stations.

-

Often used for prototypes, small production runs, or repairs.

-

Suitable for large or complex components that are difficult to automate.

Advantages of Manual Assembly:

-

Flexibility: Easy to handle small batches, custom designs, or changes.

-

Lower initial cost: No need for expensive machinery or setup.

-

Good for prototypes and repairs: Ideal when only a few units need assembly or when fixing defects.

-

Ability to assemble complex parts: Human dexterity can handle unusual or fragile components better.

Disadvantages of Manual Assembly:

-

Slow production speed: Takes more time compared to machines.

-

Higher labor cost: Requires trained workers, increasing labor expenses.

-

Inconsistent quality: Human error can cause defects or variability.

-

Not scalable: Difficult to produce large volumes efficiently.

What is Automated Assembly?

Automated assembly uses machines and robots to place and solder components on PCBs. This includes machines like pick-and-place robots, reflow ovens, wave soldering machines, and automated optical inspection (AOI) systems.

Characteristics of Automated Assembly:

-

Components are placed on PCBs by robotic machines with high precision.

-

Soldering is done using methods like reflow soldering (for surface mount components) or wave soldering (for through-hole components).

-

Used mainly for medium to large-scale production runs.

-

Requires programming, setup, and calibration of machines.

Advantages of Automated Assembly:

-

High speed and volume: Can produce thousands of boards quickly and consistently.

-

Consistent quality: Machines provide precise and repeatable placement and soldering.

-

Lower per-unit labor cost: Reduces manual labor expenses.

-

Suitable for small components: Robots can place very tiny SMT parts accurately.

-

Reduces human error: Minimizes defects caused by manual handling.

Disadvantages of Automated Assembly:

-

High initial investment: Expensive machines and setup costs.

-

Less flexible: Changes in design require machine reprogramming and new tooling.

-

Not cost-effective for very small batches: Setup costs may outweigh benefits for low volume.

-

Requires technical expertise: Skilled operators and programmers are needed to run and maintain machines.

Comparison Summary

| Feature | Manual Assembly | Automated Assembly |

|---|---|---|

| Production Speed | Slow | Very fast |

| Cost | Lower setup cost, higher labor cost | High setup cost, lower labor cost |

| Volume Suitability | Small to medium batches | Medium to large batches |

| Flexibility | Highly flexible for changes | Less flexible; requires reprogramming |

| Precision | Variable; depends on worker skill | High precision and repeatability |

| Quality Consistency | May vary | Consistent and reliable |

| Equipment Required | Basic tools (soldering iron, etc.) | Advanced machinery and robotics |

When to Use Manual vs Automated Assembly?

Use Manual Assembly When:

-

Producing prototypes or small batches.

-

Designs change frequently and require flexibility.

-

Components are large, fragile, or hard to automate.

-

Budget is limited for expensive machinery.

-

Repairs or rework are needed.

Use Automated Assembly When:

-

Manufacturing large volumes to reduce unit cost.

-

High precision and consistency are required.

-

Handling very small surface mount components.

-

Speed and scalability are priorities.

-

The design is finalized and unlikely to change soon.

Conclusion

Both manual and automated assembly processes have important roles in electronic manufacturing. Manual assembly offers flexibility and low initial costs, making it ideal for prototyping and small runs. Automated assembly excels in speed, precision, and cost-effectiveness for mass production. The choice depends on factors like production volume, budget, product complexity, and timeline. Often, manufacturers use a combination of both methods depending on the stage of product development and order size

Tags: AOI, assembly comparison, automated assembly, Automation, batch volume, complex components, cost-effectiveness, custom designs, design flexibility, electronics manufacturing, equipment investment, Hand Tools, human error, labor cost, magnifying glass, manual assembly, manual vs automated, manufacturing process, mass production, PCB assembly, pick-and-place machines, Precision, Printed Circuit Board, product development, production efficiency, production speed, prototypes, quality consistency, reflow soldering, repeatability, rework, robotic assembly, Scalability, setup cost, skilled labor, small production runs, SMT, Soldering, soldering iron, surface mount components, technical expertise, through-hole components, tweezers, wave soldering