Thin Film Technology Explained

Thin Film Technology refers to the process of creating very thin layers of material, usually just a few nanometers to a few micrometers thick, on a surface or substrate. These thin layers can have unique properties and are used in a variety of applications, from electronics and solar cells to coatings and sensors.

1. What is a Thin Film?

Imagine a piece of glass, metal, or plastic. Now, think about putting a very, very thin layer of another material (like metal, oxide, or plastic) on top of it. That layer is called a thin film. It’s so thin that it might be invisible to the naked eye, but it can have special properties that make it useful for many applications.

2. How Thin is a Thin Film?

Thin films are extremely thin! To give you an idea:

- A human hair is about 100 micrometers thick.

- A thin film is often just 1 to 100 nanometers thick. A nanometer is one billionth of a meter!

Even though it’s so thin, these films can perform complex functions, such as conducting electricity, absorbing light, or acting as protective coatings.

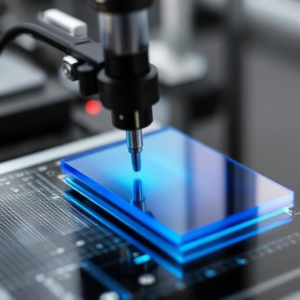

3. How Do We Make Thin Films?

There are several methods to create thin films. Some of the most common techniques are:

- Physical Vapor Deposition (PVD): This is like “spraying” vaporized material onto a surface. Think of it as turning the material into a gas, then letting it “stick” onto a surface as a thin layer. It’s similar to how a metal coating might appear on a shiny surface, like a mirror.

- Chemical Vapor Deposition (CVD): In this method, gases are used to create a chemical reaction that forms the thin film on a surface. It’s like “growing” the thin film directly on the material.

- Sputtering: This technique involves bombarding a material with ions (charged particles), causing small pieces of the material to fly off and land on a surface, forming a thin film.

- Spin Coating: For liquids, you can drop the material onto a spinning surface. As it spins, the liquid spreads out into a thin film.

4. Why Do We Use Thin Films?

Thin films have special properties that make them very useful for many industries, such as:

- Electronics: In devices like smartphones and computers, thin films are used in components like microchips, transistors, and capacitors. These tiny films can conduct electricity and control signals at the micro level.

- Solar Panels: Thin-film solar cells are a type of solar technology that uses thin layers of semiconductor material to capture sunlight and turn it into energy. These are cheaper and more flexible compared to traditional thick solar panels.

- Optical Coatings: Thin films are used on eyeglasses, camera lenses, and other optical devices to reduce glare, increase light transmission, or add color. For example, anti-reflective coatings are made of thin layers that help light pass through lenses more clearly.

- Protective Coatings: Thin films can protect surfaces from corrosion, scratches, or wear. For example, the coating on your smartphone screen is often a thin film that helps keep it scratch-resistant.

5. Advantages of Thin Film Technology

- Lightweight: Since the films are so thin, they add very little weight to the material.

- Flexibility: Some thin films can be made on flexible materials, making them useful in wearable technology or foldable electronics.

- Cost-Effective: In many cases, thin films are cheaper to produce compared to traditional bulk materials.

- High Performance: Thin films can have specific properties, like improved electrical conductivity or optical transparency, that make them better than the same material in bulk form.

6. Examples of Thin Film Applications

- Smartphones: The touchscreen and the protective coating are made from thin films.

- Solar Panels: Thin-film solar panels are becoming more popular due to their flexibility and lower cost.

- LED Lights: The thin films in LEDs help create the light and control the colors.

- Coatings for Cars: Thin films can be used to coat the paint or windshield to protect them from scratches and improve durability.

7. Challenges in Thin Film Technology

While thin films have many advantages, there are also challenges:

- Uniformity: The thin film must be applied evenly to function properly.

- Durability: Some thin films can be delicate and prone to damage.

- Scaling: Producing thin films on a large scale for commercial use can be complex and expensive.

In Summary:

Thin film technology is about applying extremely thin layers of material onto surfaces, and these films are used in many modern technologies. From smartphones and solar cells to protective coatings, thin films help make devices smaller, lighter, and more efficient. The methods to create them, like vapor deposition and spin coating, allow for precise control of the film’s thickness and properties, enabling new possibilities in electronics, energy, and manufacturing.

Tags: advanced manufacturing, anti-reflective coating, automotive coatings, capacitors, chemical vapor deposition (CVD), cost-effective materials, durability issues, electrical conductivity, electronic devices, Energy Efficiency, film uniformity, Flexible Electronics, foldable displays, high performance films, high-precision deposition techniques, LED lights, lightweight materials, mass production challenges, material science., microchips, micrometers, nano-engineering., nanometers, optical coatings, optical transparency, physical vapor deposition (PVD), protective coating, scratch resistance, semiconductor layers, smartphone touchscreens, spin coating, sputtering, substrate, surface coating, surface engineering, Thin Film, thin films, thin-film solar cells, thin-film technology, transistors, wear resistance, Wearable technology