What is ATE?

Automated Test Equipment (ATE) is a system used to test and verify electronic components, devices, and circuits without needing human intervention. Think of it like a robot that checks whether your electronics are working correctly, and it does it quickly and accurately.

Why do we need ATE?

When you create or manufacture electronic products (like smartphones, computers, or car parts), you need to make sure everything works as it should. This includes checking whether each component is performing well and within the desired specifications.

Instead of testing each piece manually (which would take a long time and could lead to mistakes), ATE automates the process. It’s like having a machine that can do all the quality control for you!

How does ATE work?

ATE systems have different tools and components that work together to test electronic devices. Here’s a breakdown:

- Test Signals: ATE generates electrical signals (such as voltage or current) that simulate how the device under test (DUT) will behave in the real world. It sends these signals to the DUT to see how it reacts.

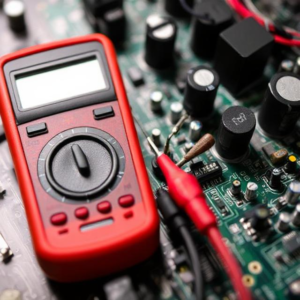

- Measurement: The ATE system measures the DUT’s response. It checks things like voltage levels, frequency, power, and other parameters. The system may use special instruments like oscilloscopes or multimeters to make these measurements.

- Comparison: Once the ATE gets the measurements, it compares them to expected results (which are the “specifications” for the device). If the DUT’s behavior is as expected, it’s “good”; if it’s different, something might be wrong with the device.

- Pass/Fail Decision: Based on the comparison, the ATE makes a decision — either the DUT passes the test or fails. This decision can be used to sort out faulty devices in a production line.

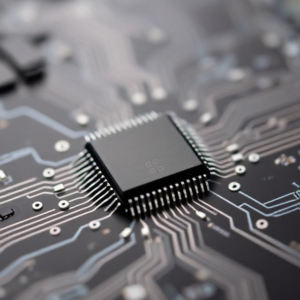

Key Parts of ATE:

- Controller: The brain of the system, usually a computer that manages all the testing processes.

- Instruments: These are the tools that measure different properties (like voltage, resistance, or signal waveform). Examples include oscilloscopes, power meters, and signal generators.

- Fixture/Adapter: This is the physical interface that connects the DUT to the ATE system. It holds the device in place and makes sure the test signals are properly sent and measured.

- Software: The software allows the ATE to execute test sequences, collect data, and make decisions (pass/fail). It also controls the test equipment and records results.

Types of Tests ATE Performs:

- Functional Testing: Verifying if the device works as intended in a real-world situation (like making sure a microchip processes data correctly).

- Parametric Testing: Measuring specific electrical characteristics of the device, like voltage levels or resistance.

- Burn-in Testing: Testing the device under extreme conditions (such as high temperature or high voltage) to see if it will fail prematurely.

- Environmental Testing: Checking how the device performs in different environmental conditions (like temperature, humidity, or vibration).

Examples of Where ATE is Used:

- Manufacturing: In factories that make electronics, ATE is used to test large numbers of devices quickly.

- R&D (Research and Development): Engineers use ATE in labs to develop new products and test prototypes.

- Quality Control: Companies use ATE to ensure that their products meet the required standards before they are shipped out.

Benefits of ATE:

- Speed: It can perform tests much faster than humans, making it ideal for high-volume production.

- Accuracy: It reduces human errors and provides consistent, reliable results.

- Cost-Effective: Over time, using ATE reduces labor costs and helps identify faulty products early in the process.

- Automation: ATE allows factories to test products 24/7 with little need for direct human involvement.

Summary:

Automated Test Equipment (ATE) is like an advanced testing robot for electronic devices. It automatically sends test signals, measures responses, and determines if the device is working as it should. It helps manufacturers ensure quality and reliability without the need for manual labor, making testing faster, more accurate, and efficient.