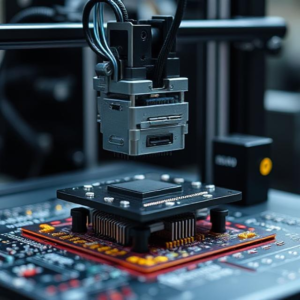

3D Printing in Electronics Manufacturing is a technology that allows manufacturers to create electronic parts or devices by building them layer by layer using a 3D printer. It’s like printing a 3D object, but instead of ink, the printer uses materials like plastic, metal, or even special conductive materials to create complex parts for electronics.

Here’s how it works in simple terms:

How Does 3D Printing Work in Electronics?

- Designing the Part:

- First, a 3D model of the electronic part is created using 3D design software (like CAD software). This model represents the exact shape and structure of the part.

- For example, this could be the case of a smartphone, a connector, or a circuit board.

- Printing the Part:

- The 3D printer reads the digital model and starts printing the part, layer by layer. It uses materials like:

- Plastic (for parts like casings or holders)

- Conductive materials (for electrical components like sensors or wires)

- Metals (for parts that need strength or heat resistance)

- The printer builds up the part from the bottom to the top, making precise, complex shapes that would be hard or impossible to make with traditional manufacturing methods.

- The 3D printer reads the digital model and starts printing the part, layer by layer. It uses materials like:

- Assembly and Testing:

- Once the part is printed, it may be assembled with other components like chips, sensors, or connectors to form the final electronic device.

- The part is also tested to make sure it works properly in the system.

Types of 3D Printing Used in Electronics

There are different types of 3D printing methods used in electronics manufacturing:

- Fused Deposition Modeling (FDM):

- This is one of the most common types of 3D printing. It works by melting a plastic filament and laying it down layer by layer to build the part.

- Use in Electronics: It’s often used for making prototypes, housings, or parts that don’t need to be electrically conductive.

- Stereolithography (SLA):

- This method uses a laser to cure (harden) liquid resin into solid parts layer by layer.

- Use in Electronics: It’s used for making detailed parts, like small connectors or housings, especially when precision is important.

- Selective Laser Sintering (SLS):

- In this process, a laser is used to fuse powdered material (like metal or plastic) into a solid form, layer by layer.

- Use in Electronics: SLS is used for making parts that need to be durable or heat-resistant, such as structural parts for electronics.

- Inkjet Printing (for Electronics):

- Inkjet printing can be used to directly print conductive materials onto surfaces. This is helpful for creating things like circuit boards or printed antennas.

- Use in Electronics: It’s used for printing circuit patterns or electronic connections directly onto materials like plastic, metal, or glass.

Benefits of 3D Printing in Electronics Manufacturing

- Customization:

- 3D printing allows manufacturers to create parts that are highly customized to fit specific needs, without the limitations of traditional manufacturing methods.

- For example, companies can design unique, one-of-a-kind parts or prototypes for a new product.

- Faster Prototyping:

- 3D printing allows engineers to quickly create and test prototypes of electronic components or devices. Instead of waiting weeks for traditional parts to be made, they can print out new designs in a matter of hours or days.

- Complex Geometries:

- Traditional manufacturing often can’t make very complex or intricate shapes, but with 3D printing, you can create very detailed designs with ease. This is useful for things like compact circuit boards or parts with unusual shapes that fit together in specific ways.

- Cost-Effective for Small Runs:

- For low-volume production or custom orders, 3D printing can be more cost-effective than traditional manufacturing methods, especially when designing new products or components.

- There’s no need for expensive molds or tooling, which can be required in traditional methods.

- Material Variety:

- 3D printing in electronics can use a range of materials, including metals, plastics, ceramics, and even conductive inks. This allows the creation of parts that are not only structural but also functional in terms of electrical conductivity or heat resistance.

Applications of 3D Printing in Electronics Manufacturing

- Printed Circuit Boards (PCBs):

- 3D printing can create custom circuit boards by printing conductive materials directly onto substrates, which could reduce the time and cost of making complex PCBs.

- Prototypes for New Devices:

- Electronics companies can use 3D printing to create and test prototypes of new devices (like smartphones, wearables, or smart home gadgets) quickly, before committing to full-scale manufacturing.

- Custom Connectors and Cases:

- 3D printing is used to make custom connectors, cases, or housings for electronic devices, allowing a perfect fit for the components inside.

- Sensors and Antennas:

- Electronics like sensors, antennas, and other small components can be printed using specialized materials, making them more affordable to produce in small quantities or customized designs.

- Wearable Electronics:

- 3D printing can be used to create parts for wearables, like custom enclosures or connectors that fit specific designs and functionalities.

Challenges of 3D Printing in Electronics Manufacturing

- Material Limitations:

- While there’s a variety of materials available, not all of them are suitable for every application. For example, some materials may not be as strong or heat-resistant as those made using traditional methods.

- Speed and Scale:

- While 3D printing is great for prototypes or small runs, it can be slower than mass production techniques like injection molding when large quantities are needed.

- Cost of High-End Printers:

- While consumer-grade 3D printers are affordable, high-end printers capable of printing with advanced materials (like metals or conductive inks) can be expensive.

Summary:

3D printing in electronics manufacturing allows companies to design and create custom parts, prototypes, or even complete devices by building them up layer by layer. It offers benefits like speed, flexibility, and the ability to make complex shapes, which makes it an exciting technology for creating everything from circuit boards to wearables. While it may not replace traditional manufacturing methods for large-scale production, it’s a powerful tool for innovation and customization in the electronics industry.